SYLLABUS

GS-3: Science and Technology- developments and their applications and effects in everyday life; indigenization of technology and developing new technology.

Context: The Union Cabinet recently approved the “Scheme to Promote Manufacturing of Sintered Rare Earth Permanent Magnets” with a financial outlay of Rs.7280 crore.

More on the News

- China has a stranglehold over the critical elements, and it had introduced export controls on the magnets in April, in response to the tariffs imposed on it by the US.

- Recently, the Indian Rare Earths Limited (IREL) planned to raise neodymium production to 500 tonnes by FY27.

Need for the scheme

- High Import Dependency:

- The country imports almost all of the 900 tonnes of the magnets used annually.

- India imported over 53,000 metric tonnes of rare earth magnets during the fiscal year ending March 2025.

- Rising Domestic Consumption:

- India currently consumes about 4,000-5,000 tonnes per annum of permanent magnets, all of which are imported.

- India’s REPM demand is projected to double between 2025 and 2030, fuelled by rising requirements in electric vehicles, renewable energy systems, industrial uses, and consumer electronics.

- Supply chain disruption: China’s export restrictions on rare-earth magnets have disrupted global supply chains, causing component shortages for Indian EV makers.

Key Highlights of the Scheme

- Establishing India’s First Integrated REPM Manufacturing Capacity: This first-of-its-kind initiative aims to set up 6,000 MTPA of fully integrated REPMs manufacturing capacity within the country.

- Creating an End-to-End Domestic Value Chain: The scheme supports facilities that cover the entire production cycle from converting rare-earth oxides into metals, processing these metals into alloys, and manufacturing finished REPMs.

- Structured Implementation Timeline: The programme will run for seven years, including a two-year gestation phase for establishing integrated facilities and a subsequent five-year period for incentive disbursement based on REPMs sales.

- Incentive Framework for Scaling Production: It offers sales-linked incentives of ₹6,450 crore over five years and a capital subsidy of ₹750 crore to develop a combined REPM manufacturing capacity of 6,000 MTPA.

- Competitive Allocation to Beneficiaries: The scheme will allocate total capacity to five beneficiaries through a competitive bidding process, with each entity eligible for up to 1,200 MTPA of production capacity.

About Rare Earth Permanent Magnets (REPMs)

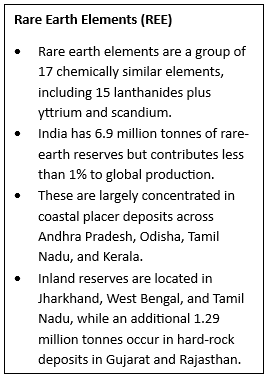

- REPMs are extremely strong permanent magnets made from alloys of rare earth elements, primarily from the lanthanide series.

- They generate magnetic field strengths above 1.2 Tesla, far stronger than conventional magnets.

- They deliver the highest permanent-magnet performance available today.

- Types of REPM:

- Neodymium Magnets (NdFeB): They offer the strongest magnetic power and the best strength-to-weight ratio, though they require protection against corrosion.

- Samarium–Cobalt Magnets (SmCo): They provide excellent resistance to oxidation and can operate at higher temperatures, even though they are comparatively less powerful and more expensive.

- Applications:

- Clean Energy and Transportation:

- REPMs are key components in traction motors and starter-generators due to their high efficiency and power density, with EVs typically using 1–2 kg of NdFeB magnets.

- They are used in direct-drive wind turbines to enable efficient energy conversion, especially in offshore installations.

- Electronics and Consumer Devices:

- REPMs drive miniature motors like voice coil motors, haptics, microphones, and camera modules, enabling precise movement and rapid response.

- Their strong magnetic properties allow the production of compact, lightweight audio and electronic components with improved performance.

- Industrial and Defense:

- REPMs boost power density and efficiency in industrial machinery and are widely used in recycling and mining to separate materials for quality control and resource recovery.

- They are critical in advanced electronics, actuator motors, and sensors, with applications in defense, including military aircraft like the F-35, for high reliability under demanding conditions.

- Medical Technology: REPMs are used in MRI machines to provide strong, stable magnetic fields for high-resolution diagnostic imaging.

- Clean Energy and Transportation:

Significance of the Scheme

- Strengthening Strategic Autonomy: The initiative reduces dependence on imported rare-earth magnets, builds long-term supply-chain resilience, and enhances India’s role in global EV and clean-energy value chains.

- Securing Domestic REPM Capabilities: By enabling indigenous production of rare-earth permanent magnets, the scheme ensures a stable and reliable supply chain essential for critical industries while supporting India’s Net Zero 2070 commitments.

- Building a Competitive Manufacturing Ecosystem: The initiative fosters a robust ecosystem for high-value REPM production, positioning India as a competitive player in global manufacturing networks.

- Alignment With National Strategic Missions: The scheme complements the Critical Minerals Mission and supports the government’s push for semiconductor and advanced materials manufacturing.

- Enhancing Energy Security: Stronger domestic manufacturing capabilities help reduce carbon emissions, cut crude-oil import dependence, and bolster national energy security.